Your Cart is Empty

Australia's favorite 3d printers in schools

The FlashForge Inventor is fully enclosed to maximize the printing success rate by creating a stable temperature inside. This also reduces noise and protects children from sticking their hands into the work area during a print.

The dual extruders move along the x/y axis via belts, and the heated bed raises and lowers, which takes care of the z plane. It has a maximum build of 230x150x160mm.

Enclosed Build Chamber

The Inventor is a fully enclosed 3d printer with a heated print surface that can heat up to 120°C.

This radiant heat passively warms the build chamber enabling the Inventor to control warping of engineering materials such as ABS.

Five temperature sensors monitor the internal environment.

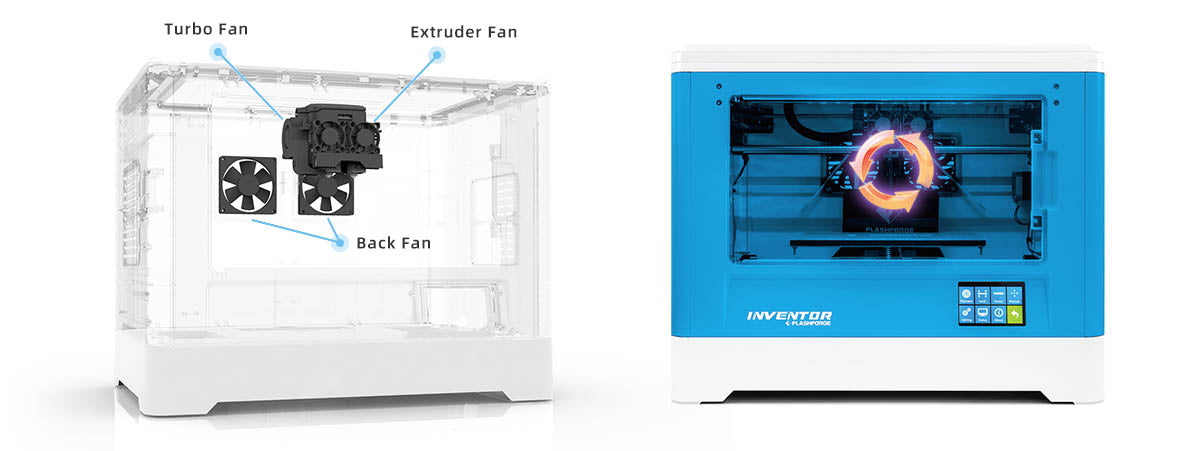

A sequence of 5 fans are controlled by the Inventor ensuring that the optimal conditions are maintained based on the nominated printing materials selected in the FlashPrint slicing software.

230 x 150 x 160mm 5.5 Litres

in both single and dual extruder mode

Perparing the Inventor for printing is a breaze with the full colour touch screen.

You can even adjust printing setting such as printing temperatures on the fly whilst the during a print without the need to re-slice a model.

Pause a print at anytime to change the filament spool for some interesting creative colour effects.

Observe your model being created from within a Wi-Fi network using the XMEye android phone application.

Send files via SD card, Wi-Fi or USB cable from your computer to the printer.

The Inventor includes 8Gb of onboard memory.

Your favorite models can be reprinted by navigating colour touch screen.

In the event of a power failure during the print process, an internal energy storage will rememder its position. Once power is resumed the printer shall prompt you to resume where it left off.

A direct drive extruder offers precise control, rapid filament retraction of extrusion ensuring clean uniform surface finish.

Air is directed to the nozzle region via a turbo fan This instantaneously solidifies melted plastic, dramatically controlling sagging of overhanging regions as well as improve the print quality of fine detailed parts.

The direct drive dual extruder of the Flashforge Inventor enable two materials or two colours within the one part.

The build platform of the Inventor can rapidly heated up to 120°C and is constructed from a and CNC machined aluminum plate ensuring flatness and excellent heat dissipation. This enables the Inventor control warping of printed parts such as ABS material.

Models are printed directly onto the durable wear resistance surface that is suitable adhere a large variety of materials including ABS, PLA, PETG and Flexible TPU.

The filament drive gears are spring tensioned, enabling the Inventor to print functional flexible TPU and elastic parts.

The multi-extrusion capability of the Flashforge Inventor enables it to print soluble support structures.

Ideal for use on parts that are traditionally difficult to 3d print with non uniform geometry, delicate detail or internal cavities.

It offers you the freedom and convenience to print delicate and complex geometries that require support, which can bed easily dissolved and wash away.

FlashPrint is the free software used to communicate with your Flashforge Inventor 3D Printer. It is used to orientate ans prepare 3d models for 3d printing. This process is known as slicing.

FlashPrint has been developed in house and is continuously updated by Flashforge engineers and can be used on their entire range of filament printers.

This fully featured and powerful slicer has been critically acclaimed for its slick interface, ease of use, slicing efficiency and advanced features.

FlashPrint advanced customised options for support structures